Latest Update: Nov 15, 2025, 5:31:54 AM

Tunnel greenhouses (also known as arched greenhouses) are an excellent entry point into modern agriculture, offering high efficiency and productivity. Their simple design, quick installation, and lower construction cost compared to other types of greenhouse structures make them a popular choice for farmers and investors.

This article, presented by Golafrooz Greenhouse Construction Company, will fully examine the process of building a tunnel greenhouse, covering everything from site selection and materials to costs and technical considerations.

What is a Tunnel Greenhouse?

A tunnel greenhouse, or arched greenhouse, is one of the most common and economical greenhouse structures. Due to its simple and cost-effective design, it holds a special place in modern agriculture. Unlike a Spanish greenhouse or other modern models, these greenhouses lack vertical walls, and their structure is designed in a semi-circular or crescent shape, resembling a tunnel.

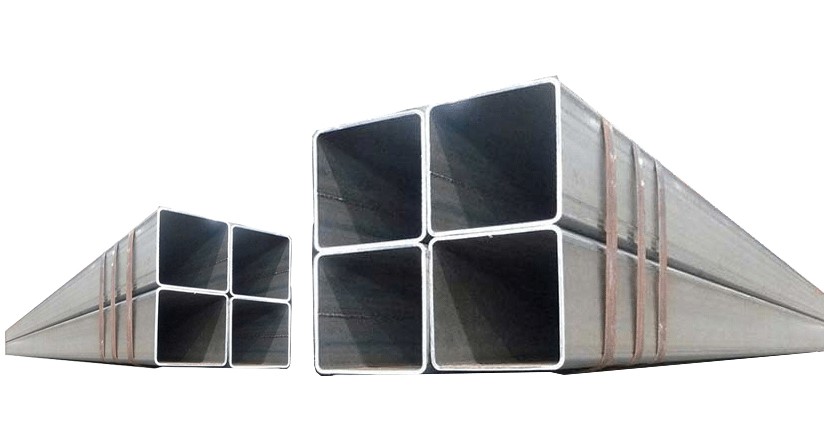

The main skeleton of the tunnel model greenhouse is usually constructed from galvanized pipes or PVC, covered with a layer of transparent plastic, $\text{UV}$-resistant film, or polyethylene. This design ensures optimal sunlight penetration and helps regulate the internal temperature for plant growth.

Tunnel Greenhouse Dimensions

-

Height: Typically constructed between 2 to 4 meters, ideal for cultivating vegetables, leafy greens, and ornamental plants.

-

Width: Often considered between 4 to 6 meters, but can be increased up to 11 meters in larger projects.

-

Length: Has no specific limitation and can be designed based on the available land.

In summary, tunnel greenhouse construction is a popular choice due to its high installation speed, low cost, mobility, and resistance to weather conditions. Its curved shape offers greater stability against wind, rain, and snow, increasing cultivation productivity.

Applications of Tunnel Greenhouses

Despite their name, tunnel greenhouses are not solely used for flowers. They are designed and built in various dimensions for multiple applications, including:

-

Mushroom cultivation

-

Medicinal herb cultivation

-

Serving as a pre-structure for restaurants, warehouses, and storage facilities

-

Cultivation of low-height summer crops (e.g., short cucumber, tomato, green bean bushes)

-

Cultivation of various leafy vegetables (e.g., mint, basil, carrots)

-

Cultivation of cut ornamental flowers

-

Cultivation of potted shrubs and tree-like houseplants

-

Covering swimming pools

-

Cultivation of off-season crops

-

Serving as a retail shop for selling houseplants

Advantages of the Tunnel Greenhouse

The tunnel greenhouse is recognized as one of the most popular types of greenhouses in Iran and globally. In addition to low construction costs and rapid installation, it provides features that significantly boost agricultural efficiency.

Key advantages include:

-

Cost-Effectiveness: Lower construction and maintenance costs compared to other types of greenhouses.

-

Quick Installation: Fast and easy installation without the need for complex infrastructure or heavy equipment.

-

Machinery Access: Allows for the movement of agricultural machinery inside the greenhouse.

-

Effective Natural Ventilation: Good natural airflow, leading to energy savings.

-

Compatibility: High compatibility with drip and low-consumption irrigation systems.

-

Increased Yield: Enhances product quality and quantity through better environmental control.

-

Cultivation Diversity: Feasibility of cultivating diverse products, from vegetables and summer crops to ornamental and medicinal herbs.

-

Scalability: The length of the greenhouse can be easily extended and expanded.

-

Modernization: Capability to integrate modern equipment like ventilation, heating, cooling systems, and conversion into a smart greenhouse.

Disadvantages of the Tunnel Greenhouse

Despite its many advantages, the establishment of a tunnel greenhouse has limitations that must be considered before investment:

-

Lower Structural Strength: The structure's lightness and plastic covering make it less resistant to severe weather conditions (strong winds, heavy rain, or snow accumulation). Reinforcement with stronger materials is required in windy or snowy areas.

-

Height Limitation: The arched roof limits the internal space, making it challenging to grow tall crops or install sophisticated equipment.

-

Temperature and Ventilation Control: Internal temperatures can rise rapidly in hot summers, and heat retention is harder in winter. Natural ventilation may be insufficient, requiring extra equipment that adds to the tunnel greenhouse price.

-

Limited Covering Lifespan: The plastic covering has a limited lifespan (usually 2 to 4 years) and must be periodically replaced, increasing maintenance costs.

-

Pest and Disease Risk: The enclosed, smaller space increases the likelihood of rapid pest and disease spread if management is not careful.

However, if the design and execution are done correctly, and the standard tunnel greenhouse plan is followed, many of these issues can be prevented or mitigated.

Stages of Tunnel Greenhouse Construction

Understanding the method of building a tunnel greenhouse is essential for farmers entering modern cultivation. The construction process should be done systematically and according to standards for the best results:

-

Selecting the Suitable Land: Choose a flat site with easy access to water and electricity. Evaluate the land's resistance to wind, precipitation, and soil slope.

-

Detailed Design and Planning: Design the tunnel greenhouse structure plan, including overall dimensions, tunnel greenhouse height and width, location of doors, vents, and irrigation systems.

-

Structure Execution: The frame is typically built using galvanized or steel pipes to ensure high resistance to humidity and weather. Arches are installed at specific intervals to form the semi-circular shape.

-

Covering Installation and Insulation: The structure is covered with polyethylene plastic or $\text{UV}$ agricultural films. These coverings protect plants from environmental factors and aid in thermal energy savings.

-

Installation of Control Equipment: Install essential equipment like ventilation systems, heaters, misters, and drip irrigation to maintain stable environmental conditions in a modern greenhouse.

-

Cultivation Bed Preparation: In the final stage, soil is amended, or hydroponic cultivation beds are prepared to ensure plants grow in a standard, enriched environment.

Tunnel Greenhouse Construction Costs 💰

The price of tunnel gree*nhouses depends on several factors, including land size, type of frame and covering, cooling and heating equipment, irrigation systems, crop type, and even the cost of greenhouse insurance.

A precise tunnel greenhouse plan must be designed first, as the design and quality of execution directly impact the final cost of the tunnel greenhouse.

Key factors in cost estimation include:

-

Structure Material: The frame is often made of hot or cold galvanized steel.

-

Covering Material: $\text{UV}$ greenhouse plastic or polycarbonate. The quality and price of various greenhouse plastics are a primary factor.

-

Technology Level: For example, the construction cost of a 1000-square-meter hydroponic tunnel greenhouse is significantly higher than a simple one due to advanced systems like smart irrigation, climate control, lighting, and automation.

-

Alternative Options: A used tunnel greenhouse can be a more economical option if the budget is limited, though its lifespan and efficiency will be lower.

For better capital management and purchasing a tunnel greenhouse, it's advisable to get an accurate estimate of the greenhouse structure price, equipment, and materials from reputable companies like Golafrooz before starting the project.

Types of Tunnel Greenhouses

Tunnel greenhouses are categorized based on shape, size, and application. The most common distinctions are:

1. Single-Unit Tunnel Greenhouse

The single-unit greenhouse is ideal for farmers and enthusiasts of home gardening. Each unit is designed independently, allowing for precise management of growth conditions (temperature, humidity, airflow). This separation minimizes the risk of pests and diseases spreading to other sections.

-

Requires sufficient plastic covering and separate installation of ventilation, heating, and cooling systems for each unit.

-

A space of about 2 to 3 meters is recommended between each unit to prevent shading and improve air circulation.

-

It is an ideal choice for a small greenhouse or home greenhouse.

2. Multi-Unit (Compound) Tunnel Greenhouse

The multi-unit or compound tunnel greenhouse consists of several tunnels connected together. By sharing structures and walls, it achieves higher efficiency and economic savings compared to single-unit greenhouses, making it suitable for large-scale production (e.g., saffron, leafy greens).

-

The internal space is divided into sections, allowing for the simultaneous cultivation and harvesting of multiple crops.

-

AutoCAD mapping of the tunnel greenhouse structure ensures a precise and standard design.

-

Connecting units complicates temperature, humidity, and ventilation control, and a problem in one section can affect others.

-

The cost of installing multi-unit tunnel greenhouse equipment is more affordable than building several separate single-unit greenhouses.

Summary

The tunnel greenhouse is one of the best options for modern agriculture due to its simple structure, arched roof, and low construction cost. Adhering to greenhouse construction principles and using a greenhouse structure map (PDF) ensures the internal space is optimized and functional, increasing greenhouse productivity. This method allows for the production of quality crops like cucumbers, strawberries, and vegetables on small plots or even at home, significantly boosting the income from greenhouse cultivation. With precise planning, appropriate placement of shelving and pathways, investing in a tunnel greenhouse becomes a sustainable and profitable economic opportunity.

However, optimal utilization of these types of greenhouses requires sufficient technical knowledge and experience in agriculture and greenhouse management.

Complete Guide to Tomato Greenhouse Construction: Soil vs. Hydroponic

Complete Guide to Tomato Greenhouse Construction: Soil vs. Hydroponic

How to Build a Cucumber Greenhouse

How to Build a Cucumber Greenhouse

How to Build a Home Greenhouse from A to Z

How to Build a Home Greenhouse from A to Z

Cost of Building a 1,000 sqm Hydroponic Greenhouse

Cost of Building a 1,000 sqm Hydroponic Greenhouse

Galvanized can profile 10

Galvanized can profile 10

Axial Fan Evaporative Cooler

Axial Fan Evaporative Cooler

Furnace Heater

Furnace Heater

Type 4 Circulation Fan

Type 4 Circulation Fan

Greenhouse Mist Sprayer

Greenhouse Mist Sprayer