Latest Update: Nov 18, 2025, 10:47:02 AM

Greenhouse Rail and Gear (Rack and Pinion) systems are used in greenhouses to move and transport irrigation systems and other equipment. These technologies are employed to increase productivity and automation in greenhouse environments. Using rails and gears facilitates the movement of irrigation systems, fertilization units, agricultural tools, and even greenhouse harvesting carts.

By utilizing these systems, repetitive operations such as irrigation and moving equipment within greenhouses are performed automatically and with improved efficiency. This leads to a reduction in time and costs related to human labor and increases the quality and quantity of product yields in the greenhouse.

Consequently, the use of rails and gears as an automation technology in greenhouses can contribute to improved performance and productivity in greenhouse agriculture.

Materials for Greenhouse Rails and Gears

Rails and gears are typically made from materials that have a long lifespan and adequate resistance. Some of the materials used in manufacturing greenhouse rails and gears include:

-

Steel: Steel is used for making rails and gears because it possesses high hardness and strength, allowing it to cope well with the environmental conditions associated with greenhouses.

-

Aluminum: Aluminum is used as a lightweight and resistant material for manufacturing greenhouse parts like rails and gears. Aluminum offers good resistance against corrosion and rust and is lighter than steel.

-

Plastic: Some parts of the rails and gears may be made of plastic materials that have suitable corrosion resistance and are lightweight.

The materials used in the construction of rails and gears may vary depending on the needs and environmental conditions of the greenhouse.

Gol Afrouz Greenhouse Company, with years of brilliant experience as a leading builder in the field of modern greenhouses, is ready to serve you all over Iran. Using up-to-date knowledge and a specialized team, we design and construct all types of Iranian, Spanish, Dutch, and Tunnel greenhouses with the highest quality and according to your needs.

Furthermore, Gol Afrouz Company provides all efficient and modern greenhouse equipment. If you are in Karaj, Tehran, or any other city in Iran and looking for a reliable partner for your greenhouse construction, contact us now through the website and benefit from the expert advice of our specialists.

Functions of Greenhouse Rail and Gear Systems

The performance of rails and gears in greenhouses is highly important and can help improve operations and productivity in greenhouse agriculture. Some important functions of this system include:

-

Equipment Transport: One of the main applications of rails and gears in a greenhouse is transferring various equipment and devices, such as irrigation systems, fertilization machines, transportation vehicles, and other tools. These transfers can occur automatically, reducing labor time and costs.

-

Motion Control: Rails and gears can help precisely control the movement of equipment and devices. This assists in regulating accurate movements and correct positioning within the greenhouse, preventing resource waste and productivity loss.

-

Automation: Using rails and gears can help automate greenhouse processes, performing operations like irrigation, fertilization, and equipment movement automatically. This leads to a reduction in costs and the time spent on repetitive activities.

Overall, rails and gears in greenhouses drive automation, improve performance, and reduce costs, contributing to productivity and production quality in greenhouse agriculture.

Advantages of Greenhouse Rail and Gear Systems

Using rails and gears in greenhouses has numerous advantages and benefits, including:

-

Automation: The use of rails and gears leads to the automation of various greenhouse processes, enabling the automatic movement of equipment, devices, and irrigation systems. This results in reduced time and costs associated with repetitive activities.

-

Efficiency and Cost Reduction: Using rails and gears leads to greater efficiency of labor and resources because operations utilizing this technology are performed automatically. This brings about cost reductions and increased speed and quality of operations.

-

Precise Control: Rails and gears allow for more precise control over the movement and positioning of equipment and devices, leading to reduced resource waste and improved product quality.

-

Safety: Since the movement of equipment is automated, these systems can improve safety in the greenhouse environment and reduce risks associated with manual movements.

Therefore, the advantages of using rails and gears in greenhouses include automation, performance improvement, cost reduction, and increased productivity.

Disadvantages of Greenhouse Rail and Gear Systems

The use of rails and gears may also come with a few disadvantages that should be considered:

-

Installation and Maintenance Costs: Installing and maintaining rail and gear systems may require significant time and money, especially if these systems are not installed and repaired correctly.

-

Durability and Lifespan: Some rail and gear systems may have lower stability and a shorter lifespan due to condensation, rust, and other factors, which can lead to a need for more frequent repair and maintenance.

-

Flexibility for Changes: Changes in the greenhouse structure or the need to change the position of equipment and devices may cause issues in using rail and gear systems.

-

Dependence on Electricity: Some rail and gear systems may rely heavily on electricity, meaning their performance could be affected during power outages or technical problems.

However, with proper planning, correct installation, and effective maintenance, the disadvantages associated with rails and gears can be minimized, allowing you to benefit from this technology in greenhouses.

Price of Greenhouse Rail and Gear Systems

The price of rails and gears used in greenhouses can vary depending on their different types, size, material, and efficiency. Additionally, costs related to installation, parts supply, maintenance, and servicing can also be influential. In some cases, rail and gear systems may have a high initial installation cost. However, it should be noted that this cost is usually considered a valuable investment over time due to the high productivity and efficiency these systems offer.

If you wish to have more precise information regarding the price of specific rails and gears you intend to use, it is best to request a price quote from reputable manufacturers or sellers to receive more accurate information.

Conclusion

In conclusion, rails and gears used in greenhouses have both advantages and disadvantages. Also, paying attention to the type of greenhouse environment and its specific needs is very important in selecting and using these systems. If you want more detailed information about the type, price, and specific applications of rails and gears in a greenhouse, it is recommended to consult with relevant manufacturers and specialists.

Complete Guide to Tomato Greenhouse Construction: Soil vs. Hydroponic

Complete Guide to Tomato Greenhouse Construction: Soil vs. Hydroponic

How to Build a Cucumber Greenhouse

How to Build a Cucumber Greenhouse

How to Build a Home Greenhouse from A to Z

How to Build a Home Greenhouse from A to Z

Cost of Building a 1,000 sqm Hydroponic Greenhouse

Cost of Building a 1,000 sqm Hydroponic Greenhouse

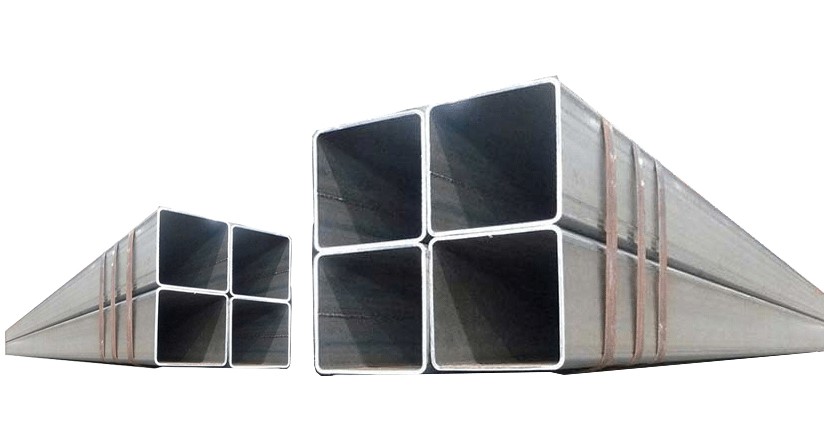

Galvanized can profile 10

Galvanized can profile 10

Axial Fan Evaporative Cooler

Axial Fan Evaporative Cooler

Furnace Heater

Furnace Heater

Type 4 Circulation Fan

Type 4 Circulation Fan

Greenhouse Mist Sprayer

Greenhouse Mist Sprayer